A roadmap to sustainability

The paper pulp sector is one of the best examples of a circular economy, due to its efficient and cascading use of renewable resources. One such resource is water, but Altri can show us more examples of reuse, recycling and energy recovery.

Celtejo hosted an event which brought together individuals, public bodies and environmental associations, where the main topic of debate was preserving the quality of the water that flows along the River Tagus, from the point where it enters Portugal to the region of Abrantes.

Altri took advantage of this opportunity to share information demonstrating its strong commitment and its water efficiency management policy, which is based on a two-pronged plan of action. The first prong is to reduce specific water consumption, by adopting measures internally; the second entails reusing waste water treated at its industrial units.

The examples presented at the Celtejo Doors Wide Open event showcase the reach and complexity of the various different measures implemented by Altri pertaining to the circular economy and in line with the United Nations’ sustainable development goals (SDG).

Sofia Reis Jorge, the Altri group’s executive director of sustainability, took part in the event outlining her vision of how all the group companies approach the issue of sustainability. “Altri believes that Environmental, economic and social development can only truly be achieved if the criteria guiding the decisions made within the Group are centred around sustainability.”

Protecting and caring for water resources

Sofia Reis Jorge explained that around 81% of the water withdrawn at the factories is put back into the environment after having been suitably treated, in compliance with all the requirements stipulated in the Sole Water Resource Permits for each industrial unit.

The other 19% either remain with the end product or evaporate into the atmosphere. Furthermore, due to the various water recovery circuits at the different stages of the process, this water can be recirculated approximately 10 times before being sent for treatment at the factories’ waste water treatment plants. Protection of water resources is not just limited to the factories.

Measures are also implemented in the forests managed by Altri, where, for example, efforts are made to avoid the inappropriate use of chemical products and other harmful substances which negatively affect the water in the area. Infrastructures are also built to preserve natural water levels and the functioning of water courses and river beds, thereby preventing them from silting up.

According to Sofia Reis Jorge, “Altri’s Forest Management is accredited by the FSC®1 and by the PEFC™2, and one of the core principles is to put in place forest management plans which cover the protection and conservation of natural resources, including water.

This is one of the reasons why Altri has for many years prioritised the responsible consumption of water, and all its factories have stipulated improvement programmes with quite ambitious goals for specific water consumption, without jeopardising the quality of the effluent produced.”

Altri therefore set itself the goal of reporting on its water management performance, by 2021, within the remit of the Water Disclosure Project (WDP), as a means of managing and measuring its water footprint.

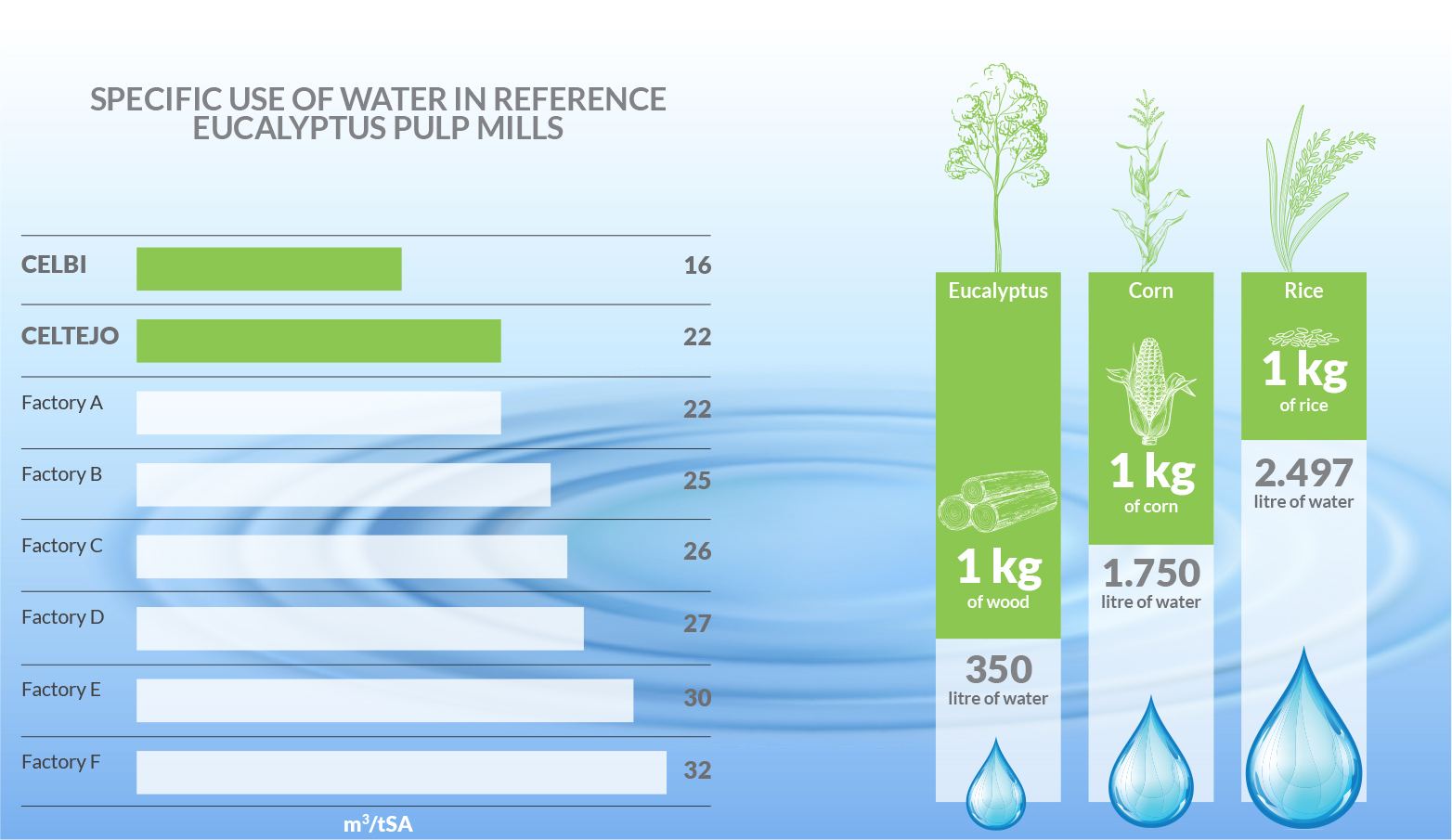

Each of the Altri factories has its own water footprint which is dependent upon the age of its machinery and type of product. As a result of the actions implemented from 2009 to 2019, Altri’s factories reduced their specific water consumption by around 45%.

Celbi and Celtejo are international benchmarks

Specific water consumption, i.e. the amount of water required to produce a tonne of pulp, currently stands at around 21 m3/adtp. This is considered the reference value for the pulp and paper sector and below the reference for the Best Available Technology (BAT) for the IPPC (Integrated Prevention and Pollution Control) and for the guidelines of the IFP (International Financial Corporation), which have stipulated from 25 m3/adtp to 50 m3/adtp as the best figures regarding global water management practices for this business activity.

The Celbi factory is considered a global benchmark with regard to specific water consumption, which has decreased by 80% since 1990. The goal has been set at 10 m3 of water per tonne of pulp by 2025. When compared with its strongest competitors which produce paper pulp using eucalyptus, the Celbi factory is more efficient in its water management, closely followed by Celtejo. Caima is a dissolving wood pulp factory, and has therefore not been included in this graph.

In terms of effluent treatment, Altri’s factories have highly efficient Industrial Waste Water Treatment Plants (IWWTP) which make sure that all effluent discharged into the receiving environments are ecologically sound and fulfil all regulatory requirements.

Celtejo aims to comply with the extremely demanding conditions stipulated in its Sole Environmental Permit, and within this remit set out a plan enabling the factory unit to evolve into a new more sustainable industrial circular economy model.

This plan took the form of an investment of around 14 million euros in the IWWTP, implementing the best technologies available worldwide, including a stage of membrane ultrafiltration treatment. This led to a decrease of around 90% in the COD, BOD and TSS parameters, thereby making the facility a global benchmark in the pulp sector.

The Celbi factory is considered a global benchmark with regard to specific water consumption, which has decreased by 80% since 1990.

Turning sludge from the IWWTP into fertilizer

Reduce, reuse, recover and recycle materials or energy. This is one of the core concepts of the circular economy which Altri is exploring in various different areas of the group. A pilot project was submitted pertaining to Celtejo, to produce fertilizer using secondary sludge created by the IWWTP which serves this industrial unit. Sofia Reis Jorge tells us how the biological sludge produced at the Celtejo IWWTP comes from the excess biomass formed as the organic material and other nutrients (azote and phosphorus) undergo biodegradation. The secondary sludge is then gravity thickened, mechanically dehydrated and sent to storage containers.

“Celtejo is strategically committed to environmental sustainability and to the circular economy, and in 2019 developed a project aimed at taking advantage of the organic material and nutrients contained in the biological sludge produced and reusing them as fertilizer in the agricultural/forestry sector.”

Their partner in the pilot project is Agristarbio, a company which owns the technology employed at the facility. According to the head of sustainability, “by reusing the biological sludge to fertilize the forest floor, we close the lifecycle of the organic material which came from the forest itself.”

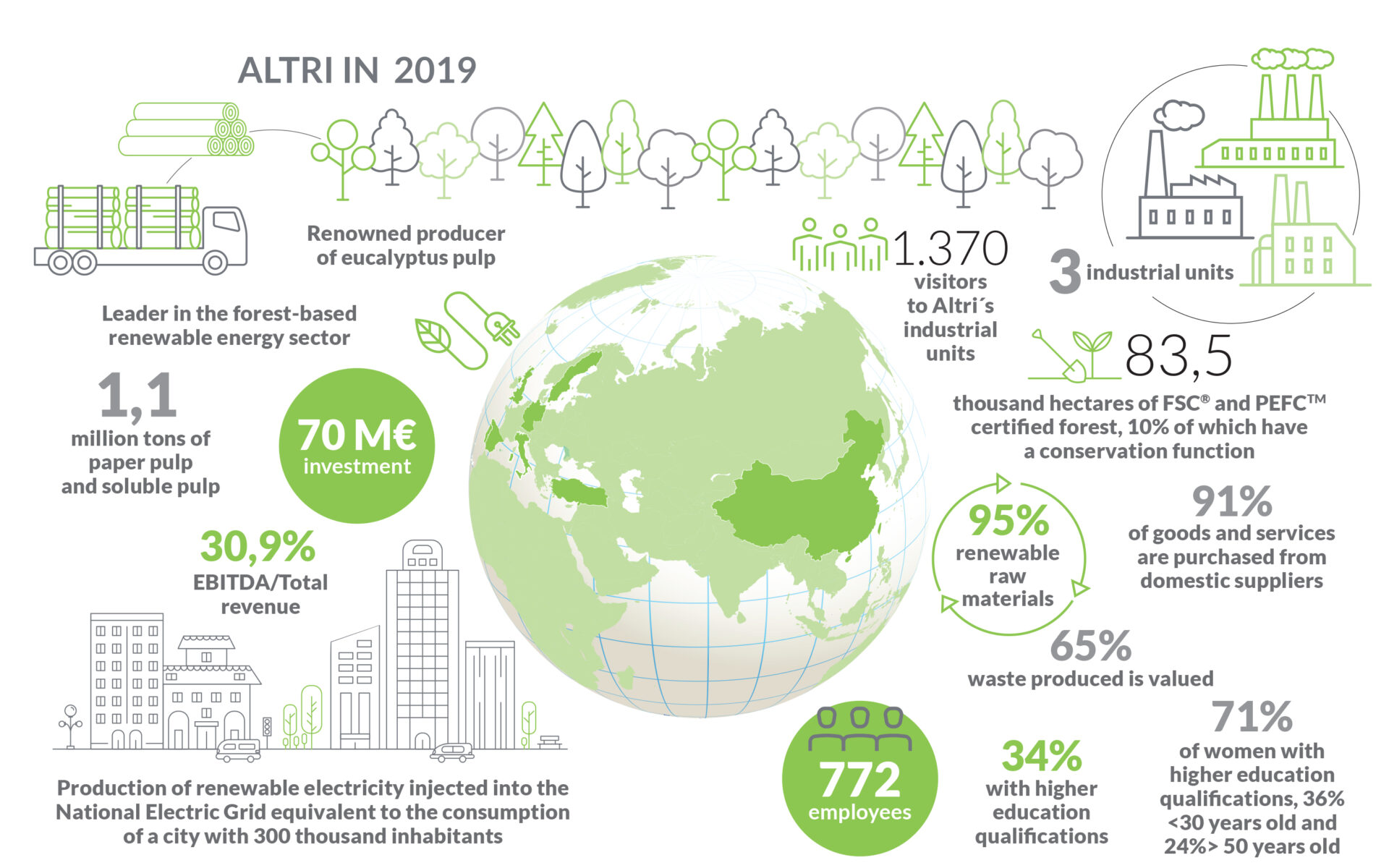

As a creator of renewable products, Altri applies the circular economy throughout its value chain – from the forests under its sustainable management, through the cellulose pulp production process, to the way in which it reuses all by-products. At Altri, around 95% of the raw materials used are renewable, and it is the Group’s strategy to “make maximum use of all by-products resulting from its processes and activities.”

A plan of action was drawn up consisting of two main areas of focus: to increase the operating efficiency of the industrial units in order to reduce the use of natural products and production of waste; and to create products of greater added value which will enable the by-products and waste produced at the factories to be used as a raw material by other industries.

The production of fertilizer to be used in the forest and the recovery of energy from residual forest biomass waste at the biomass thermoelectric power plants both served as good examples of this concept.

Business activity in line with the United Nation’s Sustainable Development Goals (SDGS)

In an ever-changing world, where consumers are increasingly informed and demanding visà-vis the origin of the products they consume and how they are produced, there are countless opportunities available to Altri, since the raw material used – timber – is sustainable, renewable and comes from non-fossil sources.

The Group occupies a preferential position, with consumers choosing alternative products to those produced from hydrocarbons. Furthermore, in the energy market Altri is one of the largest domestic producers of renewable energy using forest biomass, a by-product resulting from its industrial activity.

Some of Altri’s activities contribute directly towards nine SDGs.

Sofia Reis Jorge highlights that “Altri has been forging its own path by focusing on what it regards as crucial to creating value and to fulfilling its sustainable development goals: digital transformation, sustainable products, a culture of continuous improvement, a culture of safety, preparing the leaders of the future, responsible water use, biodiversity in its forest areas, energy efficiency and reducing the use of fossil fuels.”

Some of Altri’s activities contribute directly towards nine SDGs: Good health (SDG 3); Education (SDG 4); Clean water (SDG 6); Clean energy (SDG 7); Economic growth (SDG 8); Responsible consumption (SDG 12); Climate action (SDG 13); Life underwater (SDG 14); life on land (SGD 15).