What does Altri do in the Circular Economy?

Miguel Silva, Chief Financial Officer at Altri, addresses how the subject of the circular economy fits into the Paper and Pulp business, which has long been making use of various different by-products generated during the manufacturing process, and explains how Altri continues to seek applica ons for most of the waste produced.

Circular Economy (CE) is an expression we are increasingly hearing in our day-to-day lives. But what is the Circular Economy and when did it come about? The concept emerged from the management of industrial and urban waste of the 80s. The term Circular Economy was coined by Stahel (1976) and expanded upon by Pearce and Turner (1990), with Germany being the first country to introduce legislation in the field in 1994.

First came the concept of the 3Rs (Reduce, Reuse, Recycle), followed by cradle to grave which basically meant thinking ahead during the production planning stage about the waste generated throughout the process, in order to avoid the use of toxic materials. This finally evolved into the cradle to cradle concept, where waste is regarded as a starting point for a new product or type of use, and which generically fulfils the Circular Economy concept. This new approach differs from the traditional Take-Make-Dispose model. By reusing and recycling as much as possible, repositioning and selling products beyond their initial lifetime, the Circular Economy generates economic activity and creates employment, while simultaneously reducing environmental pressure.

Making use of by-products from the manufacturing process

The Paper and Pulp sector, and the Altri Group in particular, have long been making use of various by-products from the manufacturing process. Possibly the oldest example is black liquor which is burnt to produce energy subsequently used in the process, or the surplus sold to the grid. Other examples of the Circular Economy at Altri include selling lignosulphonates to the construction industry, making use of lime sludge in the cement industry’s kilns and using fine materials in a digestor created specifically for that purpose (this project is the first of its kind in the world).

Altri also has other Circular Economy projects at various stages of implementation, such as using Acetic Acid and Furfural at Caima or – in partnership with Agristarbio – making fertiliser using secondary sludge resulting from treating effluent from Biotek and Caima. Acetic Acid is a raw material for the chemical production chain while Furfural is a base chemical with multiple uses. Furthermore, some of the fertilisers produced using secondary sludge will be used once again within the Altri Group, to fertilise the forests cared for by Altri Florestal.

Finding applications for the waste produced

In addition to the projects currently underway, the company also aims to discover applications for most of the waste produced such as dregs, grits, carbonate mud, ash from the lime kiln and biomass thermoelectric boilers, sand and slag from the biomass thermoelectric boilers.

Altri has several projects of circular economy as the valuation of acid Acetic and Furfural in Caima or, in partneship with Agristarbio, the trnasformation in sludge fertilizers secondary from the effl uent treatment from Biotek and Caima.

If implemented, Altri’s project in Galicia will go a long way towards helping one of the world’s most polluting sectors: textile and clothing. Producing textiles using sustainable cellulose fibres (with the expectation of being able to incorporate recycled textiles in the future) will be one of the main ways of improving sustainability in a sector which uses up around 65 billion tons of raw materials annually, 80% of which becomes waste!

It’s therefore clear to see that Altri is fully committed to promoting the Circular Economy, by reusing all its by-products and striving to enhance all its waste products by bolstering their economic value, to help create a more sustainable planet.

Promotion of circular economy

Altri is fully committed to promoting the Circular Economy, by reusing all its by-products and striving to enhance all its waste products by bolstering their economic value, to help create a more sustainable planet.

The potential of the circular economy

But what’s the real potential, in global terms, of this new environmental and economic approach? A report titled “Growth within a circular economy vision for a competitive Europe” was published in 2015, and the conclusions are surprising. As well as the environmental and social benefits, the economic benefit in Europe could top 1.8 trillion euros by 2030.

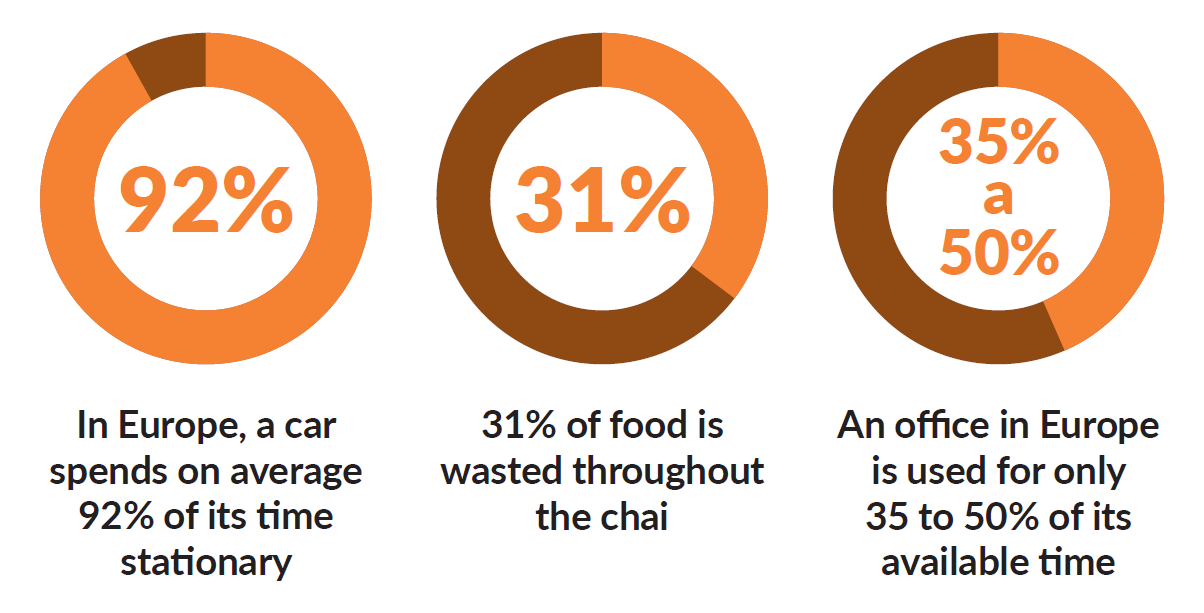

The report concludes that the Circular Economy may generate better results in terms of wellbeing, GDP and job creation than the “traditional” approach. The examples of opportunities which were identified are many and diverse, and perfectly illustrate their potential:

- In Europe, a car spends on average 92% of its time stationary;

- 31% of food is wasted throughout the chain;

- An office in Europe is used for only 35 to 50% of its available time.

By sharing cars and employing self-driving solutions, the average cost of vehicle use could fall by up to 75%. Industrial or modular processes may bring construction costs down by up to 50% and houses designed to convert solar energy could reduce energy consumption by up to 90%.

New business models

Nevertheless, switching over to a society which starts to value extending the life of products and equipment, means that business models must undergo a profound transformation. With equipment, for example, the sales relationship will very likely become a service where there is an incentive to extend the lifetime of the item. Some manufacturers already even offer a disassembly and recycling service. One example is ABB, together with its associate company Stena Recycling, where products are reconditioned and can be used to manufacture new engines or are resold to other customers.

There are probably as many challenges in the way as there are advantages, but it is vital that each and every one of us, companies and private individuals alike, does our bit so we can all live in a world where products have increasingly long lifecycles, and where waste is transformed into raw materials or other products or businesses, thereby contributing towards a more efficient and sustainable planet.